A newly developed cable connection system for electrically powered commercial vehicles and mobile machinery combines the benefits of a normal high-quality cable gland with the ease of installation of a “pluggable” connector.

As safety-relevant components, EMC-protective cable glands for use in the high-voltage vehicle electrical systems of mobile machinery and commercial vehicles must be able to withstand heavy mechanical loading and demanding thermal effects. To meet this need, the Swiss cable gland specialist AGRO has developed the EVolution EMC cable gland – an innovative connection system ensuring all-around cable shielding for the e-mobility sector. Metal Gland

The focus during the development process was on achieving firmly secured 360° shielding, in just a few assembly steps, for long-lasting EMC protection. In accomplishing this, the product had to be designed to meet the various needs of vehicle and component manufacturers and of cable assembly companies. Furthermore, the industry’s particular needs in relation to shielding and cable glanding had to be reconciled with the current standards for electric vehicles, which are based on “plugged” connections. The innovative combination of “pluggable” solution and cable gland results in significantly quicker installation in the series manufacturing of vehicles, since the plugged-in shield connections can be reliably pre-assembled in just a few carefully defined steps.

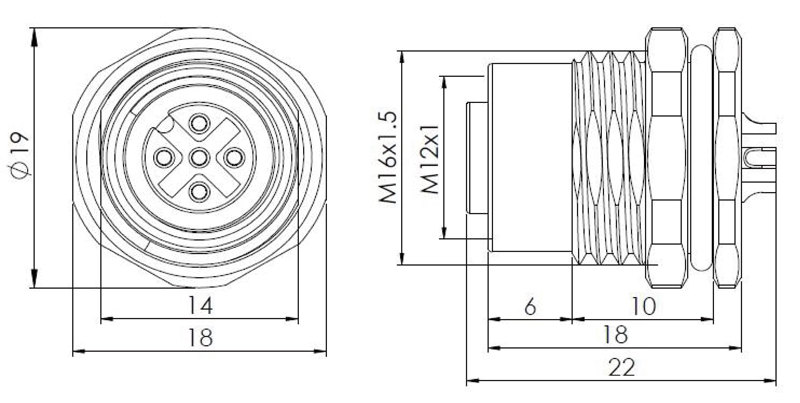

EVolution EMC is ideal for the protected feedthrough of high-voltage cables with braided copper shields and cross-sections of between 16 mm2 and 120 mm2, and of multi-core cables with smaller cross-sections. The cable gland is available with short or long connection threads in sizes M20 to M32, and is designed with protection class IP 68 or IP 6K9K. Depending on the thread size, a current-carrying capacity of up to 200 A is achieved with only minimal temperature increase. The shielding effectiveness in the frequency range from 100 kHz to 300 MHz is at least 86 dB, and the solution also offers reliable protection against interference induced by the high switching frequencies of DC/DC converters and AC transformers.

EVolution EMC’s range of applications includes permanently installed electrical equipment in commercial vehicles and construction and agricultural machinery – the cable connections of which are rarely, if ever, covered by routine maintenance and which therefore demand exceptional durability. In addition to AC inverters, drive motors, PDUs and DC/DC inverters, this also includes auxiliary drives, ancillary units such as ventilation and air conditioning compressors, coolers and steering pumps, fuel cells and, where applicable, on-board charging equipment. Another challenge relates to the connection of DC/DC converters to auxiliary devices. Due to the high switching frequencies, EMC protection of the highest standard is required, with a shield connection that ensures lifelong reliability. In general, however, the entire high-voltage vehicle electrical system requires a high level of protection since it is often subjected to parasitic electromagnetic signals, so the shielding of all power and signal cables should be EMI-proof throughout.

To achieve the necessary 360° shielding, AGRO has developed an innovative, patent-pending axial crimping technology which ensures the solution’s support ring and contact sleeve are securely fixed in position and which protects the cable shield, following crimping, from wear and damage – under even the toughest service conditions. During the crimping process, the shield is firmly connected to the cable sheath over a very short distance. This protects the cable shield from damage, and permanently fixes the EMC shield contact position. The design also enables repairs to be carried out quickly, achieving a perfect fit and without loss of performance because the cable shield is not affected by repeated removal and re-insertion of the shield contact and because the specially designed splittable sealing insert can be replaced without disconnecting the cable. The crimping work can be carried out using AGRO’s AXI-PRESS tool, a handy cordless device that securely clamps the contact sleeve onto the cable shield and the cable sheath, with a reliable 360° grip, in a matter of seconds. The factory-specified crimping force can be precisely achieved using integrated force/pressure measurement technology, and documented via an interface with a recording log produced for each individual crimping operation.

Markus Häfliger is the Innovation Driver e-Mobility at AGRO AG.

Outdoor Wire Conduit © Setform Limited 2019-2023 | Privacy policy | Archive