*Limited to most recent 250 articles Use advanced search to set an earlier date range

Sponsored by Grading Blade For Excavator

Articles can be saved for quick future reference. This is a subscriber benefit. If you are already a subscriber, please log in to save this article. If you are not a subscriber, click on the View Subscription Options button to subscribe.

Contact us at subscriptions@creamermedia.co.za

Please enter the email address that you used to subscribe on Engineering News. Your password will be sent to this address.

This content is only available to subscribers

New Komatsu Kprime tooth system delivers higher productivity and increased safety

separate emails by commas, maximum limit of 4 addresses

Sponsored by

New Komatsu Kprime tooth system delivers higher productivity and increased safety

As a magazine-and-online subscriber to Creamer Media's Engineering News & Mining Weekly, you are entitled to one free research report of your choice. You would have received a promotional code at the time of your subscription. Have this code ready and click here. At the time of check-out, please enter your promotional code to download your free report. Email subscriptions@creamermedia.co.za if you have forgotten your promotional code. If you have previously accessed your free report, you can purchase additional Research Reports by clicking on the “Buy Report” button on this page. The most cost-effective way to access all our Research Reports is by subscribing to Creamer Media's Research Channel Africa - you can upgrade your subscription now at this link.

The most cost-effective way to access all our Research Reports is by subscribing to Creamer Media's Research Channel Africa - you can upgrade your subscription now at this link. For a full list of Research Channel Africa benefits, click here

If you are not a subscriber, you can either buy the individual research report by clicking on the ‘Buy Report’ button, or you can subscribe and, not only gain access to your one free report, but also enjoy all other subscriber benefits, including 1) an electronic archive of back issues of the weekly news magazine; 2) access to an industrial and mining projects browser; 3) access to a database of published articles; and 4) the ability to save articles for future reference. At the time of your subscription, Creamer Media’s subscriptions department will be in contact with you to ensure that you receive a copy of your preferred Research Report. The most cost-effective way to access all our Research Reports is by subscribing to Creamer Media's Research Channel Africa - you can upgrade your subscription now at this link.

If you are a Creamer Media subscriber, click here to log in.

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

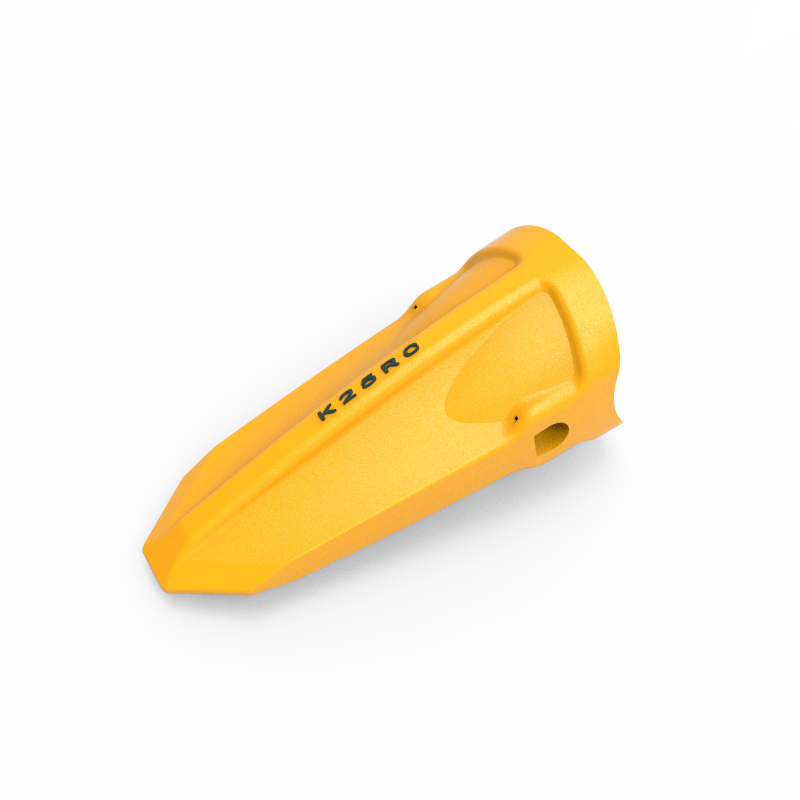

With excavator owners and operators always looking for more productive, reliable and safer tooth systems for their buckets, Kprime, a new generation of ground engaging tools now offers significant advances over previous systems.

Komatsu’s new Kprime Tooth System from Hensley Industries is now available as standard on new Komatsu excavators and has been designed as a stronger and longer lasting product, offering additional safety and productivity enhancements.

Replacing Hensley’s market leading KMax and XS Tooth Systems range of teeth, Kprime Tooth System is suitable for excavators with operating weights from four tonnes to 400 tonnes.

According to Sifiso Dubazana, Komatsu South Africa’s GET Specialist, the Kprime Tooth System builds on Hensley’s experience and expertise with its KMAX and XS Tooth system, offering significant advances in safety, ease of use and extended periods between tooth changes.

“With Kprime, we have built a truly unique product that delivers significantly more strength, productivity, reliability and is safer,” he says.

“We did this by listening to our customers and developing the best solution for their issues.

“Kprime Tooth System sets new standards for what GET should do for a customer’s business.”

Safety enhancements to the Kprime Tooth System include an intuitive locking system, pry slots on the tooth and wear cap for easier removal of worn parts, a low-torque pin for easier tooth changes, and the weight of individual units marked on each part.

Reliability has been improved through a 10 per cent stronger adapter nose design, an improved pin design that reduces the potential for accidental unlocking even after extended use, and an optimised design to reduce wear on adapters.

Stability of the tooth on its adapter has also been improved through a tighter fit.

Productivity has been significantly improved through a number of design advances, including increased wear material – so teeth don’t need to be changed so often – improved penetration, and a design that ensures the tooth stays sharp throughout its life.

“Kprime teeth are rotatable, to further extend life, while wear indicators on the wear cap and fastener let users know when those parts need to be changed,” Dubazana says.

“And losing teeth into a crusher or conveyor is far less likely to occur with Kprime due to a new locking system that means no torque loss after multiple cycles, ensuring the holding pin remains locked throughout the life of the tooth.”

A range of tooth types is available for all machine sizes across both the excavator from light-duty applications, through to the toughest and most challenging rock and abrasive material conditions.

Buckets fitted with Kprime adaptors have the option of using different styles of teeth to meet individual digging and loading requirements.

“While Kprime teeth will be offered as standard on all Komatsu excavators this system is also ideal for all other brands of earthmoving and mining equipment, from compact utility-class machines up to large mining machines,” Dubazana says.

Edited by Creamer Media Reporter

GreaseMax is a chemically operated automatic lubricator.

From batteries for boats and jet skis, to batteries for cars and quad bikes, SABAT Batteries has positioned itself as the lifestyle battery of...

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa) Receive daily email newsletters Access to full search results Access archive of magazine back copies Access to Projects in Progress Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1 PLUS Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

R1500 (equivalent of R125 a month)

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

R4500 (equivalent of R375 a month)

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Discounted prices based on volume

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

Multiple User names and Passwords for simultaneous log-ins

Mini Excavator Grading Blade Intranet integration access to all in your organisation